SAW COMPONENTS Dresden

At SAW Components Dresden, we have been developing and producing surface acoustic wave (SAW) components for over 30 years, and meanwhile many other products related to thin-film technology and nano structuring. Important pillars of our success are sustainability, quality awareness and flexibility. Our customers come to us from all over the world, from Vancouver to Kyoto, and place their trust in microelectronics from Dresden.

Our values

Competence and customer orientation instead of glib slogans. Young people and experienced professionals guarantee breaking new ground with a sense of reality. High qualification is the common characteristic of all employees, individuality included. Training and further education constantly advance the team.

Clear values provide security:

- Sustainability before quick profit

- Competence with a grip on the ground

- Products with smart ideas

- Willingness to take risks with a sense of responsibility

- Enjoyment of the job

Quality

SAW COMPONENTS Dresden GmbH knows that its reputation in the market is characterized by acknowledged high technical and economic quality. We want it to stay that way.

Our customers can rely on this:

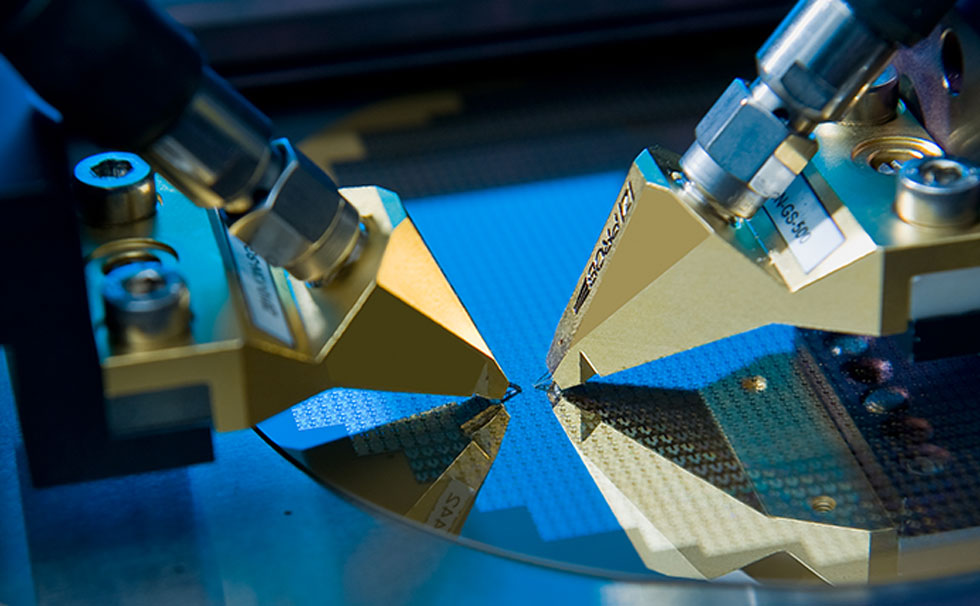

- Modern production facility with high-tech manufacturing and testing equipment

- Best quality at best price-performance ratio

- Compliance with the tightest tolerances

- Statistical process control (SPC) for all core processes

- Customer-specific quality agreements

- Careful handling of the environment, energy-optimized operation

- High quality standards and comprehensive customer support for innovations

Certifications:

- ISO 9001 since 2000

- ISO 13485 since 2023

Our History

1992 Founding team develops the core technology and basic know-how 1996 Foundation of SAW COMPONENTS Dresden GmbH 1997 Serial production for mobile phones and investment of new high-tech equipment 2000 Certification according to DIN ISO 9001 and worldwide recognition of product quality 2001 New company headquarters with development and production facility in own real estate 2003 0.3µm - process, components up to 3GHz, product portfolio is continuously expanded 2007 Development of SAW sensor technology 2009 Expansion of the packaging area 2011 First industrial SAW STRAIN solution for machine tools 2012 First SAW handheld reader 2014 Expansion of SAW sensor systems - SAW INDUSTRY and SAW ECO+ released 2017 Passivation and crossover technology, TC-SAW 2018 Manufacturing on POI wafers 2021 on beam trimming